The boiler burns low calorific value and high ash fuel, and the tail ash concentration is much higher than that of pulverized coal boiler, which will cause serious wear and lower service life of SCR reactor catalyst, and will increase the operating cost; the flue gas temperature after the coal saver is lower than that of pulverized coal furnace, and the design of 310℃ is the lower temperature limit of SCR denitrification reaction, which is not conducive to the SCR reactor to improve denitrification efficiency; as the catalyst will oxidize SO2 to SO3 and reacts with fugitive ammonia to produce ammonia sulfate and ammonium hydrogen sulfate, which will easily cause ash accumulation and corrosion in the air preheater and increase the system resistance, affecting the safety of unit operation. In view of the above factors, SCR or combined SNCR+SCR denitrification process is not considered.

Selection of denitrification process

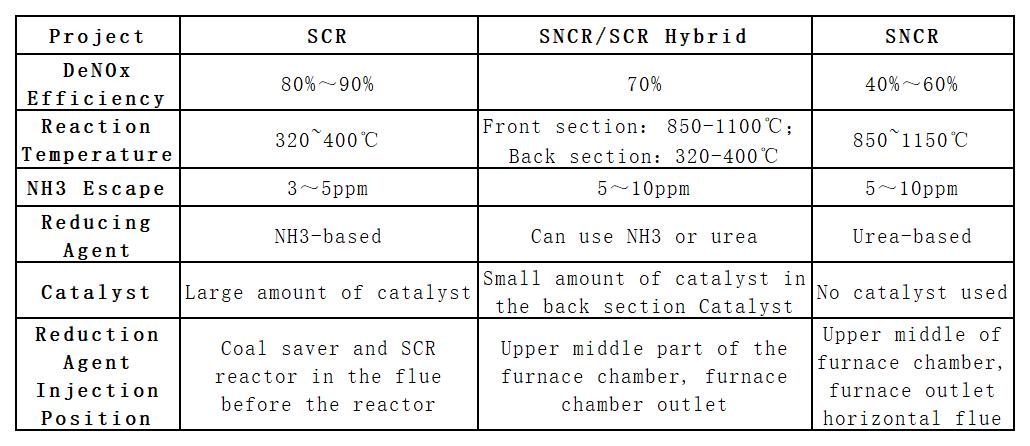

Comparison of flue gas denitrification technologies (Fujian region)

SNCRはCFBユニットに適しています。第一に、その炉出口温度は一般に850〜-1000℃の範囲内であり、SNCRプロセスの効率的な「温度ウィンドウ」内にあります。第二に、燃焼後の煙道ガスは分離器を通過するために3つのストランドに分割され、分離器内で激しく混合され、滞留時間は1.5秒以上です。また、滞留時間は 1.5 秒以上であり、SNCR プロセスに自然で優れた反応器を提供します。最後に、CFB燃焼技術は低NOX燃焼技術であるため、CFBボイラー出口のNOX濃度は低く、SNCRプロセスを通じて出口濃度は環境保護要件を保証できます。さらに、SNCRプロセスの投資と運用コストはSCRプロセスよりも低く、産業試験と海外での運転経験はすべて、SNCRシステムがCFBボイラーに使用されることを示しています。さらに、SNCRプロセスの投資と運用コストはSCRプロセスよりも低く、工業試験と海外での運用経験により、SNCRシステムは合理的な設計と50%以上の脱硝効率を備えたCFBボイラーで使用でき、アンモニアの流出はSCRプロセスよりも少ないことが示されています。 8ppm。Compared with SCR denitrification technology, SNCR denitrification technology has the advantages of simple and easy implementation, low investment and operation cost, small footprint, short construction period, and NOx emission can be reduced. The construction period is short, and the NOx emission can meet the environmental protection requirements. According to meet the layout requirements, the investment cost is economical and reasonable, and the SNCR process is recommended for this project.

2. SNCR denitrification system reductant selection

SNCR denitrification system reducing agents are liquid ammonia, ammonia and urea.

1) Liquid ammonia:

Advantages: it will quickly evaporate into gas after spraying into the furnace chamber and will not cause wet wall and corrosion on the heated surface of the furnace;

Disadvantages: ammonia is toxic, flammable and explosive, high safety protection requirements for storage, and requires approval from relevant fire safety departments for mass storage and use; SNCR using liquid ammonia is relatively complex system, high initial investment costs, high operation and maintenance costs, high pipeline losses, frequent liquid ammonia leakage accidents, and from the safety aspect, it is recommended not to use liquid ammonia as reducing agent;

2) Ammonia:

Advantages: higher jet rigidity and penetration than ammonia jetting;

Disadvantages: ammonia is malodorous, volatile and corrosive, has certain operational safety requirements, and has a complex storage and delivery system due to the large amount of diluted water it contains;

3) Urea:

Take general industrial and agricultural urea as reducing agent, its nitrogen content is above 46%, and its transportation, storage and transportation do not need special safety protection measures.

Urea as the main industrial and agricultural materials, its larger production scale manufacturers in Fujian Province, there are Sanming Chemical Factory, Fujian Fubao Tengda Chemical Co., Ltd. and other enterprises, can ensure the supply of reducing agent - urea; its price: according to the November 2012 market forecast for the urea market price in Fujian area is stable, the local urea enterprises mainstream factory offer of about 2020 yuan / ton, the recent urea manufacturers Production is basically normal, the main products for the local market demand, local agricultural fertilizer demand off-season, urea manufacturers sales are not satisfactory, urea factory quotes steady decline, the current local urea enterprises factory quotes 2000-2030 yuan / ton or so, the recent stable arrival of urea from outside the province, local dealers with the market shipments, the current local market wholesale offer 2100 yuan / ton or so.

Urea was selected as the NOX reductant from a comprehensive consideration of safety, procurement, investment, operating costs, and system complexity.

3. The choice of reductant injection point

The NOx removal efficiency of SNCR method mainly depends on the reaction temperature, the stoichiometric ratio of NH3 and NOx, the degree of mixing, reaction time, etc. The flue gas temperature of CFB boiler is generally below 920℃, and the flue gas temperature in the separator area is between 870 - 908℃, the temperature control of SNCR process is crucial. If the temperature is too low, the reaction of NH3 is not complete and it is easy to cause NH3 to escape; while if the temperature is too high, NH3 will be easily oxidized to NO, offsetting the denitrification effect of NH3. Too high or too low temperature will lead to loss of reductant and decrease of NOx removal rate.

For SNCR denitrification reductant (urea or liquid ammonia), CFB boilers can provide a suitable temperature range for the reductant to react with NOx to achieve the purpose of NOx removal.

According to the current studies on circulating fluidized bed boilers by various research institutes, the best reductant injection point for SNCR is the cyclone separator inlet. According to the flow field calculation and actual measurement of the average residence time of flue gas in the cyclone separator will be roughly greater than 1S, and the temperature in the cyclone separator basically does not change, the reductant residence time in the appropriate temperature interval will be more than 1S, more than the best reaction residence time of 0.5 seconds, which is sufficient to allow its full reaction.

CFBボイラーのサイクロンセパレータでは、ガス流の流れ場は複雑で、セパレータ入口の回転と加速、セパレータの内壁に沿った主流ガス流の回転と回転が存在します。固相の分離に伴い、ガスも壁に向かって回転し、回転プロセス中に還流ゾーンが形成され、気相の拡散と混合にとって非常に良好な条件が形成されます。

サイクロン内の気相の強力な混合は、アンモニア注入脱硝反応にとって非常に有利です。CFBボイラーのサイクロンでは、還元剤と排ガスがよく混合され、脱硝効率の向上に役立ちます。

SNCR法のNOx除去効率に影響を与える要因に従って、脱窒効率を向上させるために、還元剤注入ポイントがサイクロン入口となるように選択されます。

上記の包括的:SNCR脱硝技術は、ボイラー効率、排気温度、ボイラー加熱面およびボイラーの下流機器への影響が少なく、ユニット運転の安全性に影響を与えず、対象となる機器の改造を必要としません。SNCR 脱窒技術は、SCR 脱窒技術よりもシンプルで導入が容易で、投資コストと運用コストが低く、床面積が少なく、建設期間が短くなります。SNCR の脱硝効率は 60% に達することができ、NOx 排出濃度を 100mg/Nm3 未満に制御でき、主要地域のすべての火力発電ユニットに対する特別汚染排出制限の要件を満たします (つまり、NOx 排出量はすべて 50mg/Nm3 に達します)。手配要件を満たすと、投資コストが経済的かつ合理的になります。